Why Do You Need Specialist Chemical Footwear?

Harmful chemicals pose a wide range of health hazards (such as irritation, sensitization, and carcinogenicity) and physical hazards (such as flammability, corrosion, and explosiveness).

Employers with hazardous chemicals in their workplaces must ensure that they are labelled correctly, with safety data sheets easily accessible and that employees are trained how to handle them appropriately. Training for employees must also include information on the hazards of the chemicals in their work area and the measures to be used to protect themselves.

Assessing the Performance of Chemical Protective Footwear

EN 13832 FOOTWEAR PROTECTING AGAINST CHEMICALS

This is the European safety standard for chemical protective footwear and is divided into three parts. Part 1 deals with terminology and test methods, Part 2 with requirements for limited contact with chemicals and Part 3 with requirements for prolonged contact with chemicals. The standard is intended for use in conjunction with EN ISO 20345 (Safety footwear standard), EN ISO 20346 and EN ISO 20347 (Occupational footwear standard)

For certification to EN 13832 Part 3, boots are tested for chemical degradation over a period of 23 hours against a minimum of three chemicals from a list of 15 designated challenge chemicals contained in Part 1 of the standard, after which they must pass a series of mechanical tests. Permeation tests are then performed for the selected chemicals and normalised breakthrough must be greater than 121 minutes. Footwear approved to EN 138832 Part2 is only intended for limited contact with chemicals and is not recommended for people working with, or in proximity to, dangerous or aggressive chemicals.

Just because a boot is approved to EN13832 does not mean that it is necessarily safe to use with every chemical. Respirex test boots against a broad range of chemicals in addition to those required to pass EN13832 and you should use this permeation data to check suitability against your particular chemical (or mix of chemicals), in the same way that you would check gloves or protective clothing.

Chemical Footwear Applications

Workmaster Hazmax™ safety boots are suitable for a number of industrial, chemical, pharmaceutical and emergency situations. Hazmax™ boots are available in an Electro-Static Discharge (ESD) variant, suitable for applications such as pharmaceutical electro-protective areas. Hazmax™ FPA boots are also available which offer the same performance of Hazmax™ boots but provide increased heat resistance and conform to the EN 15090:2012 F3A Fire fighter boot standard.

Hazmax™ compact chemical protective overboots are designed to fit simply over traditional safety shoes and trainers. Hazmax™ Maxi chemical overboots are designed to be worn over safety boots.

| Applications | Hazmax™ | Hazmax™ ESD | Hazmax™ FPA | Hazmax™ Compact Overboot | Hazmax™ Maxi Overboot |

|---|---|---|---|---|---|

| Petrochemical | |||||

| Pharmaceutical | |||||

| Industrial Chemicals | |||||

| Hazardous Waste | |||||

| Emergency Services | |||||

| Electronics |

HAZMAX™ ESD

A chemically protective Electro-static discharge (ESD) boot with an integral steel toe cap and vulcanised rubber sole for superior slip resistance.

Hazmax™ compact overboots

A chemically protective front-opening overboot with a slip resistant sole designed to be worn over safety shoes and trainers.

STEP INTO ULTIMATE CHEMICAL PROTECTION

Chemical Testing

Workmaster™ boots are one of the few PPE manufacturers with our own chemical permeation testing laboratory. Having a testing lab on-site allows us to comprehensively test our products against a wide range of common chemical hazards; we can also test our products against specific chemicals or combinations of chemicals for customers if we do not currently have results available.

The Respirex™ Testing Laboratory is UKAS accredited and offers a range of chemical permeation and physical testing of chemical protective clothing, including suits, gloves and boots to European, American and international standards.

Chemical Penetration, Permeation & Degradation

Chemical Permeation is the process by which a chemical passes through a material at the molecular level. The rate of permeation will be determined by the material, its thickness and the temperature.

Actual Breakthrough Time - is the time that the chemical is first detected on the on the inner surface of the material, this will depend to an extent on the sensitivity of the detection equipment and method of analysis.

Normalised Breakthrough Time - is the time taken to reach a specific permeation rate (for European standards this is defined as 0.1μg[min.cm2], for American standards it is 1μg[min.cm2]). This is the measure used in permeation tables as it will be consistent between testing laboratories.

Chemical penetration is ingress through a material on the non-molecular level - i.e. through holes, cracks, pores, seams etc. This isn’t usually an issue with moulded footwear until it starts to age (where on some compounds chemical or UV degradation can cause brittleness and cracking), but can be a big problem with leather or synthetic fabric footwear.

Degradation is the physical change to the material caused by the chemical, which can include swelling, stiffening, wrinkling, changes in colour, and other physical deterioration. The slower the degradation occurs in the presence of a chemical, the more protective the material is for that specific chemical. Degradation tests results are subjective as they are based sole on a visual assessment of the material.

Hazmax™ Chemical Permeation DATA

Below is the chemical permeation data for the 15 chemicals listed in EN943-2:2002 & EN 13832-3:2018.

You can view the full list of chemical permeation data in the link below this table.

| CODE LETTER | CHEMICAL | CAS NO. | METHOD | BREAKTHROUGH TIME |

|---|---|---|---|---|

| A | Methanol* | 67-56-1 | EN 374-3 | Over 8 HOURS |

| B | Acetone* | 67-64-1 | EN 374-3 | Over 2 HOURS |

| C | Acetonitrile* | 75-05-8 | EN 367-3 | OVER 6 HOURS |

| D | Dichloromethane* | 75-09-2 | EN 374-3 | OVER 1 HOUR |

| E | Carbon disulphide* | 75-15-0 | EN 374-3 | OVER 1 HOUR |

| F | Toluene* | 108-88-3 | EN 374-3 | OVER 8 HOURS |

| G | Diethylamine* | 109-89-7 | EN 374-3 | OVER 2 HOURS |

| H | Tetrahydrofuran* | 109-99-9 | EN 374-3 | OVER 3 HOURS |

| I | Ethyl acetate* | 141-78-6 | EN 374-3 | OVER 4 HOURS |

| J | n-Heptane* | 142-82-5 | EN 374-3 | OVER 8 HOURS |

| K | Sodium hydroxide 40%* | 1310-73-2 | EN 374-3 | OVER 8 HOURS |

| L | Sulphuric acid 96%* | 7664-93-9 | EN 374-3 | OVER 8 HOURS |

| M | Nitric acid 50% | 7697-37-2 | EN 16523 | OVER 32 HOURS |

| N | Acetic acid 99% | 64-19-7 | EN 16523 | OVER 12 HOURS |

| O | Ammonium hydroxide 33% | 1336-21-6 | EN 16523 | OVER 32 HOURS |

| P | Hydrogen peroxide 50% | 7722-81-1 | EN 374-3 | OVER 8 HOURS |

| Q | isopropanol | 67-63-0 | EN 16523 | OVER 32 HOURS |

| R | Sodium Hypochlorite 16% | 7681-52-9 | EN 374-3 | OVER 8 HOURS |

| S | Hyrdofluoric acid 48% | 7664-39-3 | EN 374-3 | OVER 66 HOURS |

| T | Formaldehyde 37% | 50-00-0 | EN 374-3 | OVER 8 HOURS |

| Ammonia Gas* | 7664-41-7 | EN 374-3 | OVER 8 HOURS | |

| Hydrogen Chloride Gas* | 7647-01-0 | EN 374-3 | OVER 8 HOURS | |

| Chlorine Gas* | 7782-50-5 | EN 374-3 | OVER 3 HOURS |

Chemicals in bold* are the 15 standard test chemicals defined in EN 943-2:2002

download FULL CHEMICAL PERMEATION DATA

TRUSTED BY FIRST RESPONDERS & SAFETY EXPERTS

ESD Vs ANTISTATIC Footwear

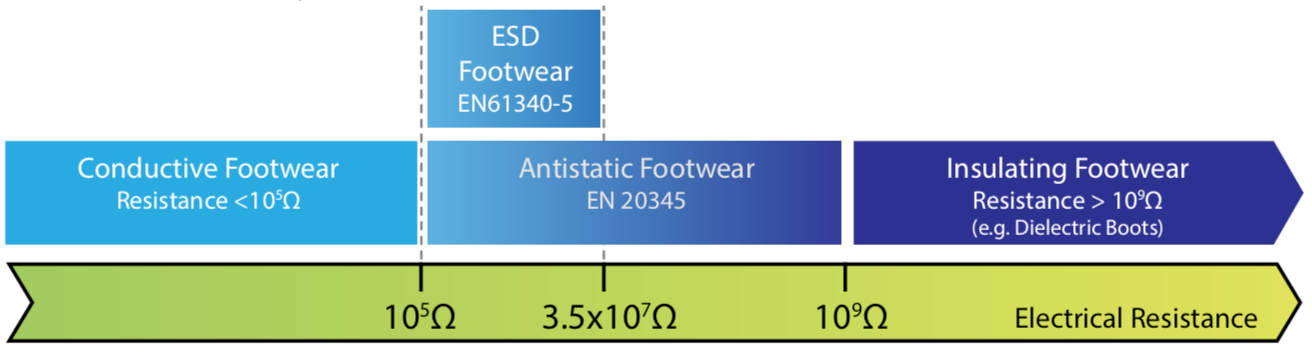

According to EN 20345: 2011, a shoe or boot is considered to be antistatic if its’ measured electrical contact resistance falls between 100 kΩ (105 ohms) and 1 GΩ (109 ohms). With a lower resistance, a shoe or boot is considered to be conductive and at higher values, to be insulating. This 100kΩ to 1GΩ range is regarded a sensible compromise, giving protection from electrostatic build up and protection from electrical shocks at lower voltages.

For some industries the risk of uncontrolled electrical discharge (sparks) in potentially explosive atmospheres or the protection of sensitive electronic components and devices are also important considerations. In these situations, another standard for Electro-Static Discharge (ESD) control applies: EN 61340-5-1 (“Electrostatics. Protection of electronic devices against electrostatic phenomena”).

For ESD footwear the lower limit of electrical resistance is 100 kΩ (the same as for antistatic footwear) and the upper limit is 35 MΩ (3.5 x 107 ohms). This means that a boot that is ESD-capable is by definition also antistatic at the same time. Conversely, not every antistatic boot is ESD-capable e.g. If an electrical resistivity of 100 MΩ is measured, the shoe is antistatic but outside the ESD limits. If the shoe has an electrical resistance of only 1 MΩ, it is both antistatic and ESD-capable.